Maintenance and use of cow dung organic fertilizer granulator

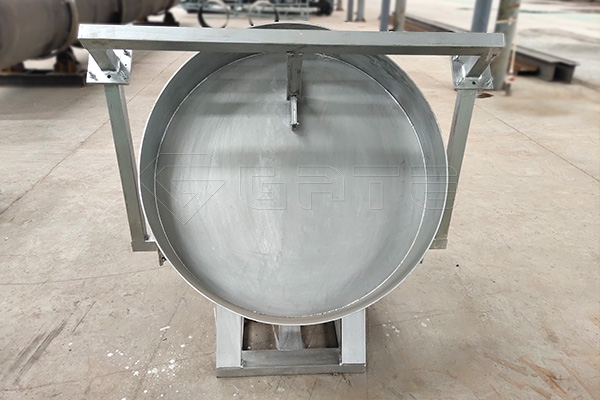

The cow manure organic fertilizer granulator is suitable for granulation of organic fertilizer, compound fertilizer, compound fertilizer and organic-inorganic compound fertilizer. Due to the high granulation rate, the time is large, the operation is stable, the equipment is sturdy and durable, and the service life is long, and the majority of users choose the ideal granulation equipment. The cow manure organic fertilizer granulator is more important among the organic fertilizer equipment. It has a direct impact on the quality of the granular organic fertilizer. The roundness, uniformity and fertilizer retention and fertilizer retention of the fertilizer are not small.

Applicable scope of cow dung organic fertilizer granulator

The cow dung organic fertilizer granulator is suitable for various non-stick materials in the form of powder, material or small pieces, such as pulverized coal, cement, clinker, limestone, shale, coal gangue, clay, etc., powdery, granular or small. Block material. The cow dung organic fertilizer granulator can be widely used in gold processing plants, coal mining plants and chemical, infrastructure and mechanized foundry workshops. The machine has simple structure, convenient adjustment and superior performance. The cow manure organic fertilizer granulator is suitable for materials with a particle size of not more than 50 mm, and is not suitable for conveying materials with high viscosity, not easy to flow, and materials with particularly good fluidity.

Maintenance of cow dung organic fertilizer granulator

The gear reducer of the cow dung organic fertilizer granulator replaces the gear oil every 3 months. Check the working condition of the motor reducer frequently. Fill the bearing block with butter, clean the agglomerates in the disc, and check

whether the bolts and nuts in all parts are loose.

Application Method of cow dung organic fertilizer granulator

1. Check whether the gear reducer is filled with gear oil before starting and starting. Whether the disc rotates in the correct direction.

2. The cow dung organic fertilizer granulator runs, the main engine starts after pressing the start button, and observes whether the equipment is running normally, whether there is vibration or not, and whether the rotation is flat.

3. After the filler and equipment are in normal operation, they can be added and water is added.

4. After granulation adjustment and packing, the angle of the disc can be adjusted according to the requirements to make the granules reach the required size.

Leave a Messages