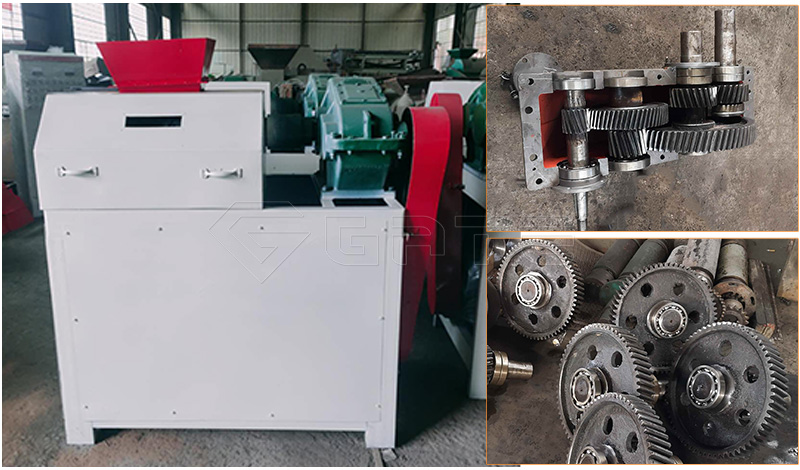

dry granulation double roller compaction granulator for compound fertilizer production plant

Introduction of Dry Granulation Double Roller Granulator

Dry Granulation Double Roller Granulator is the dry granulation and key equipment for compound fertilizer production plant. the double roller granulator uses squeezing principle to form fertilizer particles with diameters of 3.5-10mm in one time. The shape and size of the ball socket on the roller shell can be customized by customer. Dry type fertilizer Double Roller Granulator has higher granulating ratio of over 95%. With no drying technology, materials will be pressed into ball shape to meet the requirements of compound fertilizer production in Compound Fertilizer Double Roller Granulator .

Feature of Dry Granulation Double Roller Granulator

1. No drying process, normal temperature granulating, one-step forming in Mineral Fertilizer Double Roller Granulator

2. Low energy consumption and no waste water or gas emission

3. Easy operation and maintenance, no need installation of Double Roller Granulator

4. Press rollers adopt new metal which is resistant to corrosion, wear and impact.

Advantage of Dry Granulation Double Roller Granulator

1. Reasonable structure, machines will be tested before transporting and roller will be polished in perfect using

2. Wide application scope: no only for NPK fertilizer production, but for cat litter working

3. High granulating ratio, higher than 95% in Double Roller Granulator

4. No drying need, simple working make big benefits

5. Environmental working, low energy consumption and no waste emission from Double Roller Granulator for Fertilizer Production

Working principle of Double Roller Granulator

This series of Double Roller Granulator suppler is extruded model, and its working principle is: Electromotor drive the belt and pulley, then it is transmitted to the driving shaft by the speed reducer, and by synchronizing the open gear with the passive shaft, achieving the working in the same direction. Material is added from the hopper, after the Double Roller Granulator manufacturer roll extrusion forming, demoulding pelletizing; and through a chain, the balls are transferred to the broken screen studio, sieving and isolate the finished products (the balls), then return to mix with new materials and granulate again.

Dry Granulation Double Roller Granulator for NPK Compound Fertilizer Production Plant

Double Roller Press Granulator / Double Roller Compacting Granulator for compound fertilizer production line

By the belt conveyor, the well mixed raw materials are conveyed to the pan feeder, which feeds the materials evenly into the four roller press granulator or roller compaction granulator under the feeder through the hopper. By the counter-rotating high pressure rollers, the materials are extruded into slices. The slices flow down to the crushing chamber under the press roller, where they are crushed by the crushing rollers and screened to get the required granular. The press rollers adopt new type metal which is resistant to corrosion, wear and impact.

Compound fertilizer production line or Compound fertilizer plant is mainly used for producing Compound fertilizer. The line adopts double roller press granulator which has large capacity for fertilizer granulation, and no need drying, having small investment and low power consumption.The press rollers of the compound fertilizer granulator machine can be designed to make different shapes and sizes of materials.

Leave a Messages