How to produce high quality organic fertilizer granulator with disk granulator?

With the vigorous development of organic fertilizer equipment, disc granulator has been recognized by more and more people, but the expectation of disc granulator has also increased. How to produce high-quality organic fertilizer particles with disc granulator has become an important difficulty of disc granulator. Here we summarize the impact of disc granulator. Three factors of machine production:

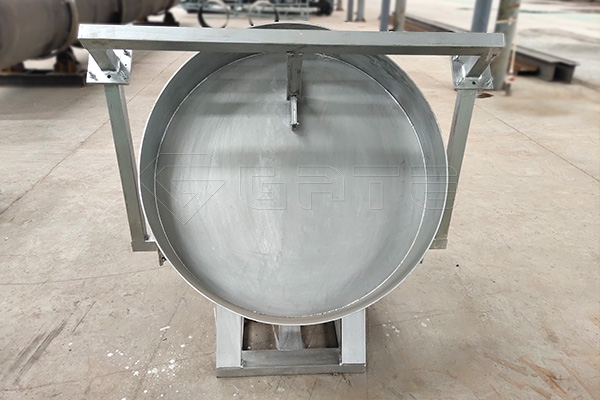

1, diameter of disk granulator

The diameter of the disk granulator is mainly determined by the output, according to the production capacity and other equipment requirements for selection, but the diameter of the disk granulator is too large over 5 meters, in the manufacture of

organic fertilizer particles there are certain difficulties.

2, the tilt Angle of the disk granulator

The tilt Angle of the disk granulator should be greater than the natural resting Angle of the wet raw material before granulation, otherwise, the material will bond to the disk, rotating with the disk, so as to achieve the purpose of granulating powder in the disk granulator disk.But if the tilt Angle of the disk granulator is too large, the material will be piled up at the bottom of the disk granulator disk, can not roll on the disk into grains, the final discharge is basically powder, granulation rate is too low.

3, the speed of the disc granulator

As the fine powder rises as the disc of the disc granulator rotates, it rolls off under the force of gravity. At the same time, due to the centrifugal force, it is twisted toward the edge of the disc of the disc granulator, and the powder particles are close to the collision and are bonded together under the surface tension of the liquid phase. Therefore, the speed of the disc granulator will affect its bonding and granulation process.

Leave a Messages