Organic fertilizer production granulator equipment Manufacturer

Technical parameters of Organic fertilizer production granulator equipment:

| Model | Power

(kw) |

Capacity

(t/h) |

Rotate Speed

(r/min) |

Drum Size | Granule Diameter

(mm) |

Dimension

(mm) |

Granulating Ratio | Inlet Moisture |

| GTZJ-60 | 37 | 1-2 | 1450 | Φ600*1800mm | 3-5 | 4500*1500*1050 | >95% | 20%-40% |

| GTZJ-80 | 55 | 2-3 | 1450 | Φ800*2400mm | 3-5 | 4900*1700*1250 | >95% | 20%-40% |

| GTZJ-100 | 75 | 3-5 | 1450 | Φ1000*3000mm | 3-5 | 5300*1900*1400 | >95% | 20%-40% |

| GTZJ-120 | 90 | 6-8 | 1450 | Φ1200*3000mm | 3-5 | 5700*2100*1700 | >95% | 20%-40% |

| GTZJ-150 | 110 | 8-10 | 1450 | Φ1500*3000mm | 3-5 | 6200*2800*2000 | >95% | 20%-40% |

Application range of Organic fertilizer production granulator equipment:

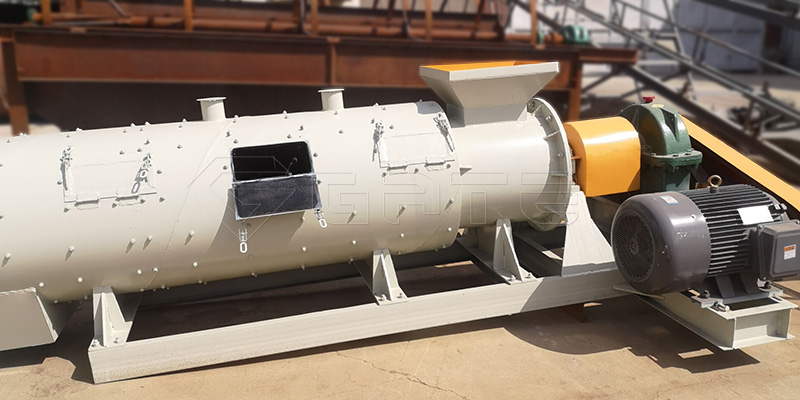

The Organic fertilizer production granulator equipment is GATE Factory’s newly developed new organic fertilizer granulator, also known as the stirring tooth granulator.

Organic fertilizer production granulator equipment is especially suitable for the granulation of light fine powder materials. The finer the basic particles of the fine powder material, the higher the sphericity of the particles, and the better the quality of the ball. Typical application materials for Organic fertilizer production granulator equipment : chicken manure, pig manure, cow dung, charcoal, clay, kaolin and so on.

Main parts of Organic fertilizer production granulator equipment:

Organic fertilizer production granulator equipment is a combination of motor, transmission, rotor, cylinder and frame.

1.Organic fertilizer production granulator equipment adopts Y series national standard motor, which has the characteristics of strong power, energy saving, reliable quality and overload operation.

2.Organic fertilizer production granulator equipment is made of special materials and processed by special process. It has the characteristics of high bearing capacity, stable operation, durable parts and safe and reliable work.

3.Ordinary fertilizer production granulator equipment rotor is divided into three parts:

1) Shaft: The large shaft is made of special materials and specially made.

2) Stirring teeth: Organic fertilizer production granulator equipment is made of special material, hard and wearable, and can be adjusted in length.

3) Stirring head: The head of the stirrer head is made of gold steel cutter head.

4.Organic fertilizer production granulator equipment is divided into three parts: the feed mixing section, the granulation section and the polishing section.

Installation and commissioning for Organic fertilizer production granulator equipment:

1. Installation: Organic fertilizer production granulator equipment is required to lay precast concrete table before installation, and fix the base of the granulator on the table with anchor screws, which is convenient for the operation of Organic fertilizer production granulator equipment and also prevents the granulator from moving. There is also a need to pay attention to the transport of the material of the leather conveyor should be aligned with the inlet and outlet of the Organic fertilizer production granulator equipment, or the pit can be used for material transportation.

2. Commissioning: After the installation of Organic fertilizer production granulator equipment, it is necessary to check whether the components of the granulator are tight. Then carry out the no-load test, and carry out the no-load operation for 8 hours without interruption. The temperature of each bearing should rise steadily. The temperature of each component of Organic fertilizer production granulator equipment should not be 50 degrees Celsius at the end of the test run. Severe wear and abrasion.

Leave a Messages