Structure of Double roller fertilizer press granulator

Preface for Double roller fertilizer press granulator:

Today GATE fertilizer production line manufacturer would like to share the structure of the double roller fertilizer press granulator for you all. And hope you can learn more about Double roller fertilizer press granulator if you need.

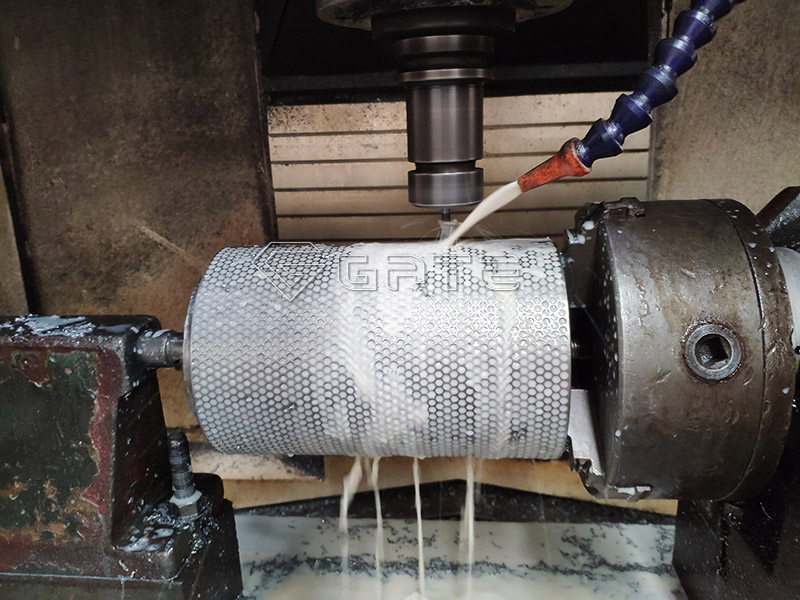

Structure of Double roller fertilizer press granulator:

1.Double roller fertilizer press granulator is composed of a frame, two pressure rollers, and has auxiliary bearings, reduction gears, fixed speed or variable speed drive. A gasket (positioning bracket) between the bearing housings prevents the pressure rollers from contacting and can adjust the pressure roller spacing.

2. The frame of the Double roller fertilizer press granulator should be designed so that all forces are absorbed into the frame without being transmitted outward. The two rollers are brought closer by a hydraulic piston. In this hydraulic system, a safety valve can be provided to prevent an overpressure when foreign matter falls between the rolls of double roller fertilizer press granulator.

3. The double roller fertilizer press granulator is composed of a roller shaft, a roller body and an additional press type device. The surface of the stamper can be made into one solid or divided into several segments, which are suitable for hot press forming because it is easier to control the thermal expansion of the device. The material of the press roll of double roller fertilizer press granulator is harder and more resistant than the integral roll. abrasion.

4. In order to make all kinds of loose density materials can be sent to the bite entrance of the pressure roller, Double roller fertilizer press granulator can apply various feeding devices.

For materials that can flow smoothly, a gravity feeder with a control feed rate device can be used for the double roller fertilizer press granulator. For fine powder materials with bridging and adhesion tendency, the loose packing density is low, and some forced feeders must be used to achieve the purpose of exhausting, pre-pressing and supercharging when the material is sent to the bite of double roller fertilizer press granulator. This type of feeder can be used to control the feed rate automatically with a variable speed motor.

When the nature of the feed material changes, the control system can adjust the operating conditions, and the Double roller fertilizer press granulator can also obtain a uniform product.

Leave a Messages