Which kind of granulator is better in the production of organic fertilizer granules

From the function of the division of organic fertilizer granulator

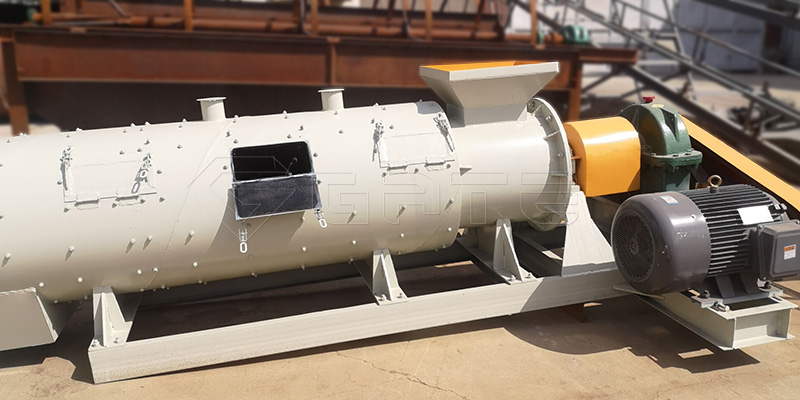

1. The new type of organic fertilizer granulator, wet tooth-stirring granulator, new type of compound granulator, drum granulator, etc., is more suitable for making organic fertilizer granulator with animal husbandry manure and plant straw

2. Disc granulator is suitable for coal powder, cement, clinker, fertilizer and other materials to make compound or compound fertilizer molding, or to do organic fertilizer granulation molding with soil with high organic matter content

3. Roller extrusion granulator, drum granulator, flat mold granulator suitable for compound fertilizer, compound fertilizer, especially rare earth fertilizer, potash fertilizer, ammonium bicarbonate series compound fertilizer granulation.

Animal manure, residues and straw to make organic fertilizer selection

New type organic fertilizer granulator, wet tooth stirring granulator, new type compound granulator are all suitable, they all adopt wet continuous push rod granulation new technology design and manufacture. This machine not only can a variety of organic compounds for granulation, especially to the use of conventional equipment granulating of crude fiber materials, such as: crops straw, wine residue, mushroom residue, medical, animal dung, etc., after fermentation can granulation, the new type of organic fertilizer granulator, wet mixing granulator, a new kind of composite granulator and humic acid and raw materials such as sewage sludge granulation effect also achieve very good effect.

Which kind of place is the organic fertilizer disc granulator suitable for?

Disc granulator is an open inclined turntable granulator, which is widely used in the shaping of pulverized coal, cement, clinker, fertilizer and other materials. Disc granulator has no drying process, normal temperature granulation, one-time forming, less investment; small power, reliable operation, no three wastes discharge, stable operation, convenient maintenance, reasonable process layout, advanced technology, low production cost.

Where is the highlight of the counter-roll extrusion granulator?

The process flow of the counter-roll extrusion granulator is short, the energy consumption is low and the output is large. The direct granulation of dry powder does not need the follow-up drying process, which is more conducive to the convergence and transformation of the existing production process. The strength of granules produced by roll extrusion granulator is high, and the increase of accumulation ratio is more significant than other granulation methods.

Leave a Messages