Why choose GATE pellet making machine?

The production process of small organic fertilizer equipment is as follows:

1. Production process

On the yeast fermentation pool – evenly into the bacterium agent – turn heap fermentation, fermentation 12 to 15 days – out of the pool – points screen – crushing – to mix – (granules) packaging – for sale

2, organic fertilizer production equipment

1) slot stacking machine

Three fermentation tanks with a width of 9 meters and a length of 45 meters shall be built according to your production scale. The fermentations shall be continuously put into the fermentation tank and transferred three meters to the other end of the fermentation tank by the heap turning machine every day. At the same time, the purpose of moisture regulation and even mixing can be achieved.And can achieve the goal of full rot.

2), forklift truck

Use shovel to transfer the fermented organic fertilizer of fertilizer granulator to the semi-finished products stacking area, which is convenient for daily processing of the fermented organic fertilizer thrown to the top of the heap turning machine and out of the pool in time.

3) screening machine

The fermentable organic fertilizer of organic fertilizer granulator will be sifted, the inside of the bulk and debris out of the easy to next step crushing and packaging.

4) shredder

After sorting out the large pieces of debris and stones in the sifted organic fertilizer of organic fertilizer granulator, the products will be crushed, which is beautiful and can ensure the quality of the products.

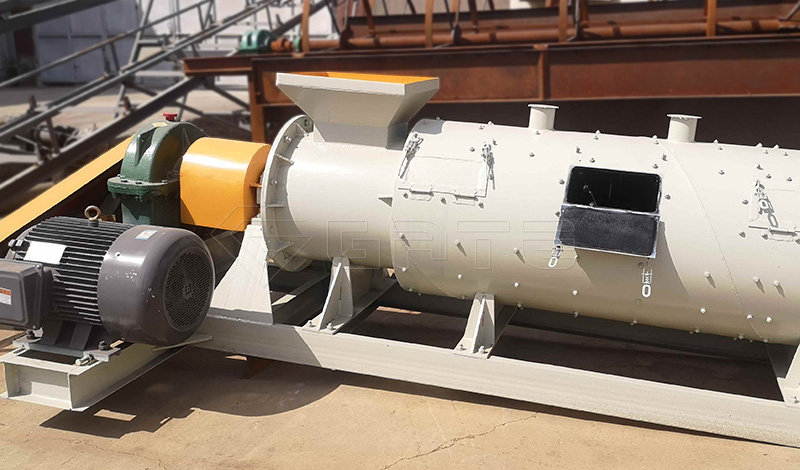

5) premix machine

Mixing the sifted and crushed organic fertilizers of organic fertilizer granulator can ensure the stability of product quality and play a mixing role in adding fertilizers and trace elements for production of special fertilizers and various compound fertilizers.

6) packaging machine

Premix evenly after the organic fertilizer granulation if need to granulation, if do not need granulation direct packaging sales.

The function of the product

the raw materials are uniformly fed into the feeding hopper by the quantitative feeder of organic fertilizer granulator, and the tying machine USES a pair of rollers with holes in the holes, leaving a gap between each other, and the two of them rotate in reverse at the same speed.

The roller bearing seat does not move in the frame, while the other set of roller bearing seat moves on the guide rail of the frame, pressing each other with the help of hydraulic cylinder.Rolls of organic fertilizer granulator are regularly arranged in many shapes on the surface

A hole of the same size and shape, and the trough is aligned with the trough.At this time, the dry powder material from the top of the two rollers of organic fertilizer granulator continuously and uniformly by self-weight and forced feeding into the two rollers,

After entering the bite area, the roller gradually bites into the trough.With the continuous rotation of the roller, the space occupied by the material is gradually reduced and gradually compressed, and the forming pressure value is reached.

Then, the pressure gradually decreases, and the shaped block falls off the hole hole due to the elastic recovery and self-weight, and enters into the crushing and screening device. The finished product of organic fertilizer granulator is granular qualified product, which has been carried out

Balance packing.The fine powder and unqualified particles come out of the powder mouth and then enter the feeder mouth of the elevator with fresh materials mixed into the pre-feeding hopper and enter the next round of work

Art process.

Leave a Messages