What are the common granulation processes for compound fertilizers?

Common granulation processes of compound fertilizer include drum granulation, disc granulation, spray granulation, and high tower granulation. Each granulation process has certain advantages. Which process is used depends on your actual needs, material type and actual budget, because the price of each granulator is different for each process.

1.Drum granulation

Drum granulation is also called drum granulation. Drum granulator is the most widely used equipment in the type of compound fertilizer production equipment. The main working mode is granulation wet granulation. After a certain amount of water or steam, the basic fertilizer is fully chemically reacted in the cylinder, and under certain liquid conditions, the rotation of the cylinder is used to make the material particles Produces a crushing force to agglomerate into a ball.

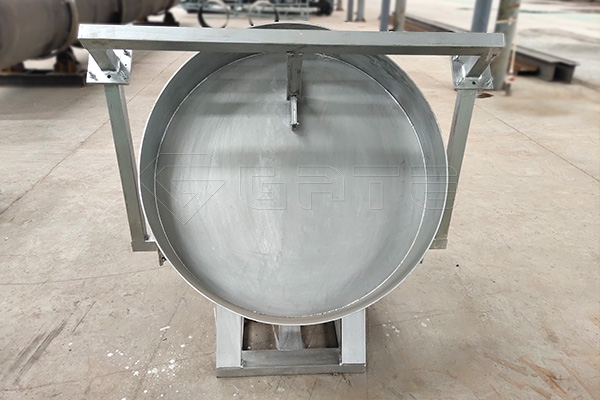

2. Disc granulation

The principle of the granulation of the disc is that all the raw materials are mixed and then enter the disc granulation, and the disc is rotated to make the materials agglomerate into balls. Disc granulation is characterized by simple equipment, low investment, and quick launch. The disadvantage of disc granulation is that it is only suitable for small-scale production, the efficiency is low, the daily output is only tens of tons, and the formulation is limited, and it needs viscous materials, which is only suitable for low concentration.

3.Spray granulation

Spraying mostly refers to urea spray, which is to melt the urea and spray it into the compound fertilizer granulation device to reduce the urea crushing process. If the urea plant is connected to the urea plant, the cost is saved. Fertilizers dissolve quickly, and most of them are high-nitrogen formulas with nitrogen greater than 20.

4. Ammonia granulation

Ammonia granulation compound fertilizer is a process of ammoniation and secondary dechlorination granulation. The principle is that potassium chloride and sulfuric acid are added to the reaction tank to heat and react under certain conditions, and the escaped HCL gas can be absorbed by water. A certain concentration of hydrochloric acid is obtained, and the generated potassium hydrogen sulfate is mixed with dilute phosphoric acid to form a mixed acid. The mixed acid and the synthetic ammonia are reacted in a tubular reactor in proportion, and the compound fertilizer slurry is directly sprayed into the drum granulator to form a certain proportion of the sulfur-based compound fertilizer of nitrogen, phosphorus and potassium. It has the characteristics of uniform granulation, bright color, stable quality, sufficient nutrients, easy dissolution and absorption by crops, especially for seed fertilizers.

The high tower is a high-temperature melting or compounding of the compound fertilizer material, which is thrown from a high altitude, and the surface tension causes a spherical shape when scattered. Screen again. The particles are less likely to agglomerate because they have less moisture during the high temperature process. The material is fully mixed and the particles are crystal clear. Selling is good. The reaction materials require high purity, high concentration formula, and the urea ratio is relatively high.

Leave a Messages