Henan Gate Organic Fertilizer Granulator

Henan Gate Heavy Industry Machinery Technology Co., Ltd. is a company mainly engaged in the production of large and medium-sized series of organic fertilizer equipment and compound fertilizer equipment. The main products are: annual production of 10,000-200,000 tons of organic fertilizer and compound fertilizer equipment. Organic fertilizer fermentation, granulation, crushing, drying and screening equipment. The organic fertilizer granulator is the key equipment for producing organic fertilizers such as livestock manure, straw and other organic fertilizers in the organic fertilizer production line. It makes the organic fertilizer raw material into granules, makes the organic fertilizer shape good, and improves the utilization rate of the fertilizer. Fertilizer granulation equipment In addition to organic fertilizer granulators there are many other types, disc granulators, flat granulators, drum granulators. Organic fertilizer granulator plays an important role in organic fertilizer production due to its unique structure and granulation process.

The organic fertilizer granulator makes a significant contribution to the realization of pollution-free agriculture. In addition to the normal growth of crops, most of the fertilizers are washed away by rainwater, which also leads to heavy metal pollution

of soil and agricultural products, eutrophication of water bodies, water, soil and environmental pollution, and avoids unfavorable factors. Fertilizer factors reduce pollution to water, soil and the environment, and reduce threats to human and

animal survival. Conducive to the ecological environment. The organic fertilizer granulator is beneficial to the mass production of organic fertilizer, and the use of organic fertilizer in agriculture helps to improve the environment.

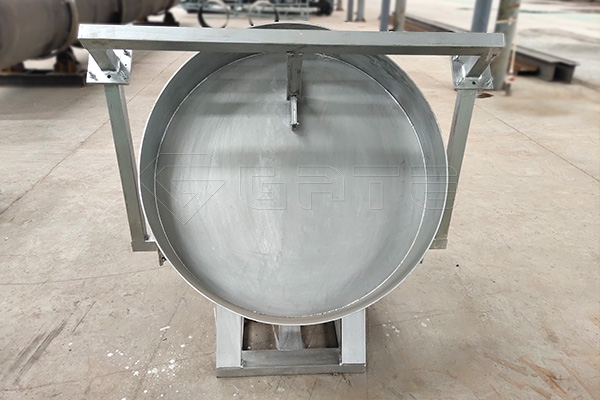

Fertilizer granulation equipment – Disc granulator

The granulation disc adopts an overall circular arc structure, and the granulation rate can reach 93 or more. The granulation tray has three discharge ports, which facilitates intermittent production operations, greatly reduces labor intensity and

improves labor efficiency. The reducer and the motor are driven by a flexible belt, which makes the starting smooth, slows the impact force and improves the service life of the equipment. The bottom of the granulation disc is reinforced with a number of radiant steel plates, which are sturdy and durable and never deformed. The thickened, weighted, and sturdy base design eliminates the need for anchor bolts for smooth operation. Disc granulator is widely used in the processing of bio-organic fertilizer spherical particles, such as coal powder, cement, clinker, fertilizer and other materials.

Introduction of the advantages of the disc granulator

1. No drying process, granulation at room temperature, one molding, less investment, quick effect and good economic benefit.

2. The power is small and reliable, no three wastes are discharged, the operation is stable, the maintenance is convenient, the process layout is reasonable, the technology is advanced, and the production cost is low.

3. Wide adaptability of raw materials, can be used for granulation of various raw materials such as compound fertilizer, medicine, chemical, feed, coal, metallurgy, etc., and can produce various concentrations and types (including organic fertilizer,

inorganic fertilizer, biological fertilizer). , magnetic fertilizer, etc.) compound fertilizer.

4. Especially the granulation of rare earth, ammonium bicarbonate and ammonium sulphate compound fertilizer is a promotion project of national environmental protection applicable technology.

Leave a Messages