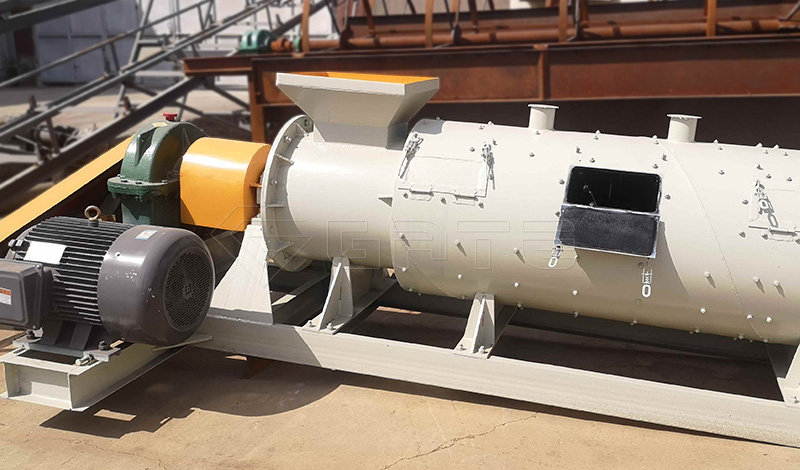

1-10t / h New Type Organic Fertilizer Granulator in Gate

The energy-saving New Type Organic Fertilizer Granulator processes the organic material after composting into organic granular fertilizer. Re-use of crops can effectively improve the fertilizer of crops, recycle agricultural resources, and effectively solve environmental problems. Our New Type Organic Fertilizer Granulator is mainly used in bio-organic fertilizer production lines with a capacity of 1-10 tons / hour.

This series of New Type Organic Fertilizer Granulator is a new patented product jointly developed by our company and the Agricultural Machinery Research Institute. It is designed and manufactured using wet continuous pusher granulation. New Type Organic Fertilizer Granulator can not only granulate various organic substances, but also produce organic granular fertilizer from chicken manure, cow dung, pig manure, crops, industrial waste, domestic garbage and the like. It is especially suitable for crude fiber materials that are difficult to granulate in traditional equipment, such as crop straw, wine residue, mushroom residue, dregs, animal droppings, etc. Granulation can be carried out after fermentation, and it is also possible to achieve better granulation effect on acid and municipal sludge.

New Type Organic Fertilizer Granulator features

1, the organic content can be as high as 100%, to achieve pure organic granulation·

2, the use of organic particles under a certain force, can be inlaid with each other’s characteristics, no need to add binder when granulation.

3, the particles are solid, can be sieved after granulation.

4. New Type Organic Fertilizer Granulator reduces drying energy consumption.

5, the organic matter after fermentation does not need to be dried, the raw material moisture content can be 20-40.

6, can be added special rubber sheet lining or acid-resistant stainless steel lining to better solve the material sticking to the drum

New Type Organic Fertilizer Granulator specifications

|

Model |

Capacity (t/h) | Power (kw) |

Weight (kg) |

|

XZ80 |

2-4 | 15 |

6500 |

|

XZ100 |

3-5 | 22 |

8200 |

|

XZ120 |

4-7 | 30 |

9400 |

|

XZ150 |

6-10 | 37 |

10500 |

|

XZ180 |

8-12 | 45 |

14500 |

Leave a Messages