Easy Operation Organic & Compound Fertilizer Chain Crusher

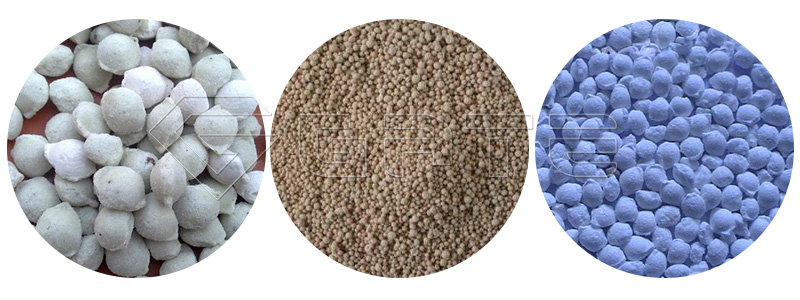

Chain crusher is mainly used to crush various materials into small granules.The grinding medium can be fertilizer, concrete,coal, rocks,etc. Our chain crusher is specially designed for production of bio-organic fertilizer. It can be used individually or in conjunction with other fertilizer equipment

It is also an impact crusher with single rotor, the end of the rotor with steel-made link chain and the other end fitted with wear-resisting chain header crush the impact of the pad via a high speed rotating chains. The machine uses hard alloy chain plate of synchronous speed with the high-intensity and wear-resistance in the process of crushing and has rational design, which makes materials uniformly broken, uneasy to stick wall,easy to clean.To prevent materials stuck and friction of the steel plate,we set up lined rubber sheet in the body of the machine and provide with quick-opening access doors at either side of the body.

Working Principle of Easy Operation Chain Fertilizer Crusher

1. It adopts the operating way that rotating chains can have multiple forces on the materials in the inner part, making materials collide against each other due to their movement. Then motor-driven chains undergo the high-speed rotation to create the crushing impact on the materials.

2. Materials enter the inside of the machine via the feeding equipment and follow the rotation of the chains. Meanwhile, owing to the centrifugal force, materials hurled to the inside and then the inner wall can be crushed again. Next, the standard finished materials are discharged via the outlet.

Cage mill smaller size compared with other crushers attributes to its rational design in feeding and impacting. The cage mill for fertilizer crushing shafts installed on the round disc constitutes a rotating cage to create impact force and crush materials.

Fertilizer feeds from the side feeder and is crushed by the shafts on the disc. The crushed materials drop and go through a second time impact.With the increasing of rotors, the particles are much smaller and finer. The sideway feeding makes the materials spread uniformly on the disc during its rotation.

Leave a Messages