Organic fertilizer disc granulator installation and use precautions

The organic fertilizer disc granulator is one of the widely used equipments in organic fertilizer equipment. In the process of use, it is necessary to pay attention to the operation specifications and installation specifications, so as to effectively improve production efficiency and extend the use of specifications. Service life. According to historical feedback, many people are using the disc granulator in the process. Due to improper operation and installation failure, the equipment damage and granulation effect are not ideal. Granulator use precautions

Organic fertilizer disc granulator use precautions:

1. Control of moisture in the operation of organic fertilizer disc granulator. In the working of the disc granulator, the inclined turntable pellet process is adopted, and the agglomeration process has higher requirements on the moisture content, and the moisture control is not good, which may cause the particle granulation rate to decrease. Therefore, during the processing, it is necessary to observe the changes in the moisture control of the granulation material by the sprayer.

2. Control the quality of the material during the filling to ensure that no impurities or large particles are mixed in the feed. Also pay attention to the equipment feed temperature. The temperature of the die is too high, and the material tends to be unstriped and bonded to the die after starting up.

3. Pay attention to the change in the inclination of the organic fertilizer disc granulator. The disc granulator has a certain inclination. If the inclination angle changes due to accidental reasons, it will affect the granulation rate of the organic fertilizer granules and also affect the service life.

4. Pay attention to the temperature change of the body of the fat disc granulator. You can touch the sliver with a clean hand. If the strip does not touch the hand, heat it up immediately and raise it to the strip. Ensure that the temperature of the equipment is stable when running, do not go up and down. Also need to pay attention to the temperature near the vent hole to the head of the machine to maintain about 200 degrees Celsius.

5. When using the organic fertilizer disc granulator, in order to ensure the smooth and complete production of the particles. Care should be taken to ensure that the feed is uniform and sufficient, and the feeding speed of the equipment and the feeding speed should be matched to avoid the deterioration of the quality and output of the pellet.

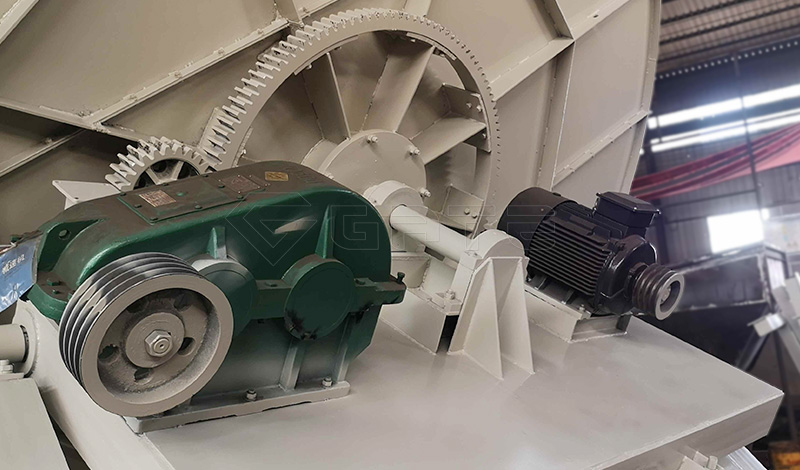

6. When the body of the disc granulator is unstable, check whether the gap of the coupling is too tight. It should be loosened in time. If the bearing part of the reducer is hot or accompanied by noise, it should be timely. Overhaul and refuel.

Precautions for the disc granulator in the assembly process of the organic fertilizer production line:

1. During the installation of the organic fertilizer disc granulator, the main body should be kept perpendicular to the horizontal, and the verticality verification and correction should be performed after the installation is completed.

2. Before installing the organic fertilizer disc granulator, the concrete foundation should be well installed, installed on a horizontal concrete foundation, and fastened with bolts.

3. Before the organic fertilizer disc granulator is energized, it is necessary to ensure that the power supply meets the power requirements set by the disc granulator, and the power line and control are configured according to the power of the equipment.

4. After the installation of the organic fertilizer disc granulator is completed, check whether the bolts in each part are loose and the main door is tight.

Leave a Messages